Ama-electrode e-graphite anamandla aphezulu kakhulu asetshenziswe kabanzi kulezi zici ezilandelayo:

1.Ukubumba kwe-graphite kokusakazwa okuqhubekayo nokuncane kancane kwezinsimbi ezingezona ayoni

Eminyakeni yamuva nje, izindlela ezithuthukisiwe zokukhiqiza ezifana nokukhiqizwa okuqondile okuqhubekayo (noma okungaqhubekayo) kwamabha noma amashubhu asuka esimweni sensimbi encibilikisiwe kuye kwakhuthazwa kokubili ekhaya naphesheya. Le ndlela isiqalile ukwamukelwa eShayina ezicini ezifana nethusi, ama-alloys ethusi, i-aluminium ne-aluminium alloys. I-graphite yokwenziwa ithathwa njengento efanelekile kakhulu yokubunjwa kokubunjwa okuqhubekayo noma okulinganayo kwezinsimbi ezingenayo insimbi. Umkhuba wokukhiqiza ufakazele ukuthi ngenxa yokwamukelwa kwesikhunta se-graphite, esinokusebenza okuhle kokushisa (i-thermal conductivity inquma isivinini sokuqiniswa kwezinsimbi noma ama-alloys) kanye nokusebenza okuhle kokuzigcoba kwesikhunta, akukhona nje ukuthi ijubane lokuphonsa liyenyuka, kodwa futhi ngenxa yokuthi usayizi we-inget unembile, ubuso bushelelezi, futhi inqubo yokucubungula i-crystalline ingaba iyunifomu ngokuqondile. Lokhu akugcini nje ukwandisa kakhulu isivuno semikhiqizo eqediwe futhi kunciphisa ukulahlekelwa kwemikhiqizo yemfucuza, kodwa futhi kuthuthukisa kakhulu izinga lemikhiqizo.

Kunezinhlobo ezimbili zezindlela zokulingisa eziqhubekayo: ukusakaza okuqhubekayo okuqondile kanye nokusakaza okuvundlile okuqhubekayo.

2. Isikhunta sokukhipha ingcindezi

Izinto ze-graphite zokwenziwa zisetshenziswe ngempumelelo ekuphonsweni kokucindezela kwezinsimbi ezingenayo insimbi. Ngokwesibonelo, ingxubevange ye-zinc nengxubevange yethusi okukhiqizwa isikhunta sokucindezela ukucindezela okwenziwe ngezinto zokwenziwa zegraphite kuye kwasetshenziswa ezingxenyeni zezimoto nakwezinye izici.

3. Ukucindezela okushisayo kufa

Ukucindezela okushisayo kwe-graphite okwenziwayo kunezici ezilandelayo lapho kusetshenziswa ekufakweni kwengcindezi ye-carbide enosimende:

Okokuqala, uma izinga lokushisa elicindezelayo liphakanyiswa ku-1350-1450 degrees, ukucindezela kweyunithi edingekayo kungancishiswa ku-67-100 kilograms force per square centimeter (okungukuthi, ingxenye eyodwa kweshumi yokucindezela okubandayo). Okwesibili, ukucindezela nokushisa kwenziwa ngenqubo efanayo, futhi umzimba ominyene we-sintered ungatholakala ngemva kwesikhathi esifushane sokucwilisa.

4. Isikhunta sokwenza ingilazi

Ngenxa yokuqina kwamakhemikhali ezinto ze-graphite, ukumelana kwazo nokumanziswa yingilazi encibilikisiwe, kanye neqiniso lokuthi aziguquli ukwakheka kwengilazi, kanye nokumelana nokushaqeka kwazo okushisayo kanye nezinguquko ezincane ezihambisana nezinga lokushisa, seziphenduke izinto ezibalulekile zokubumba ekwenziweni kwengilazi eminyakeni yamuva nje. Angasetshenziselwa ukwenza isikhunta samashubhu engilazi, amashubhu endololwane, amafaneli, namanye amabhodlela engilazi amise okwesipesheli.

5. Sintering uyafa nabanye

Kusetshenziswa i-thermal deformation encane kakhulu yezinto zokwenziwa ze-graphite, ukubunjwa kwe-sintering kanye nabakaki be-transistors kungenziwa. Manje isisetshenziswa kabanzi futhi isiphenduke into ebaluleke kakhulu ekuthuthukisweni kwemboni ye-semiconductor. Ngaphezu kwalokho, isikhunta se-graphite sibuye sisetshenziswe ekubunjweni kwensimbi eyinsimbi, isikhunta esiqinile sezinsimbi ezihlukahlukene ezingezona ayoni, isikhunta sensimbi ekhonjiwe, isikhunta sezinsimbi ezingamelana nokushisa (njenge-titanium, zirconium, molybdenum, njll.), kanye nezibunjwa zokubunjwa kwe-aluminothermic welding for rails welding, njll.

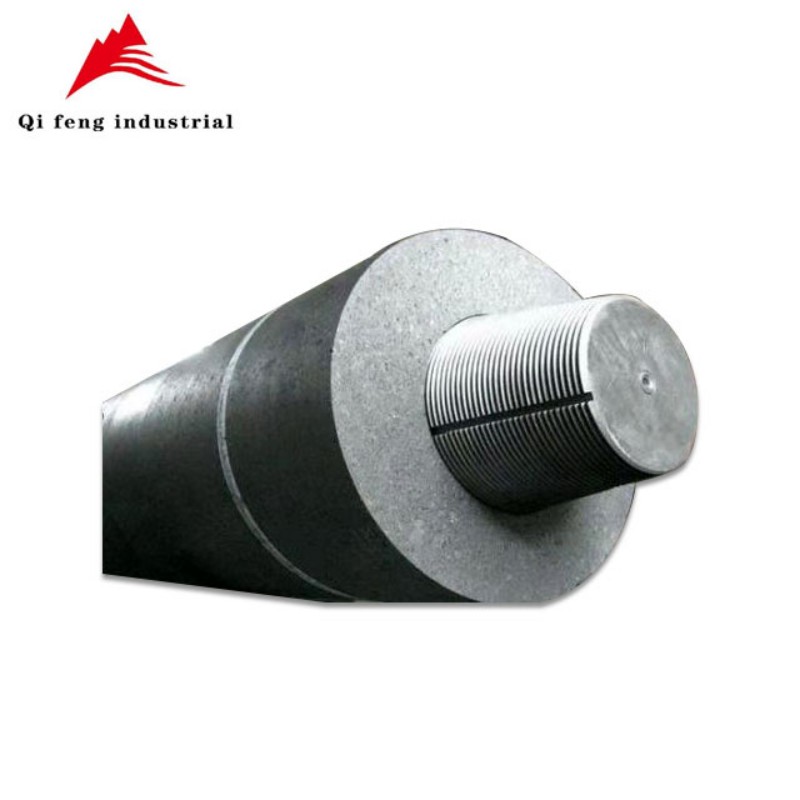

6. Isikhunta se-graphite sokusakazwa kwe-centrifugal

I-Mold graphite isetshenziswe ngempumelelo ekubunjweni kwe-centrifugal. I-United States yamukele isikhunta sokwenziwa se-graphite esinogqinsi olungaphezu kwamamilimitha angu-25 ukuze kufakwe imikhono yethusi emaphakathi. Ukuvimbela umonakalo ovuthayo wesikhunta se-graphite yokwenziwa, izinyathelo ezithile zokulwa ne-oxidation zingathathwa. Ngemva kokuphonsa inombolo ethile yokubunjwa, uma indawo yangaphakathi yesikhunta itholakala ukuthi ishisiwe, ubukhulu bomgodi ongaphakathi wesikhunta bungakhuliswa ukuze busetshenziselwe ukuphonsa imikhono emikhulu. I-Qingdao Mingyuan Fengyue New Materials iwuhlobo olusha lwebhizinisi lokucubungula i-graphite elinekhwalithi ephezulu ye-flake graphite powder njengomzimba walo oyinhloko kanye nemikhiqizo ye-graphite yobuchwepheshe obuphezulu njengomkhiqizo wayo ohamba phambili. Isungule ubudlelwano bokubambisana besikhathi eside namayunithi angaphezu kuka-200 asekhaya nawangaphandle futhi iye yanconywa kakhulu iningi labasebenzisi.

I-Nanometer graphite powder yenziwe nge-flake graphite yemvelo njengempahla eluhlaza, icutshungulwa ngemishini ekhethekile yokuchotshozwa kwemishini nezindlela ezikhethekile zokukhiqiza. Njenge-nanoscale graphite powder, i-nanometer graphite powder inezinhlobonhlobo zezicelo ngenxa yobukhulu bayo bezinhlayiya ezincane, okuqukethwe kwekhabhoni ephezulu, kanye nokugcotshwa okuphezulu okuhle kakhulu, ukuqhutshwa kagesi okuphezulu, ukumelana nokushisa okuphezulu, njll. Ububanzi bokusebenza be-nano-graphite powder butholakala emikhakheni yokukhiqiza yezimboni ezifana nokugcoba nokuhamba.

Izinhlayiya ze-nanometer graphite zilungile futhi zinezinhlayiyana ezinhle zokuminyana. Zakha ungqimba oluqinile futhi olucishe lungagqoki oluvikelayo oluboshwe ngamakhemikhali endaweni yensimbi. Angabuye axutshwe nezinto ezingezona e-conductive njengama-resin kanye nerabha kanye nemikhiqizo yepulasitiki ukwenza izinto ezihlanganisiwe eziyinhlanganisela. I-nanometer graphite nayo ingenziwa ibe yizingubo zokugqoka. I-composite conductive coatings etholwe ngokungeza ama-conductive fillers anezindawo zikagesi ezihlala isikhathi eside futhi ezinzile. Inezinzuzo ze-conductivity enhle ye-thermal, i-conductivity kagesi enhle kakhulu kanye nokumelana nokugqwala okuphezulu kakhulu. I-Nanometer graphite inosayizi wezinhlayiyana ezifanayo, ukuhlanzeka okuphezulu, nomsebenzi ongaphezulu. Iphinde ibe nokuhamba kukagesi okuphezulu nokusebenza kokugcoba, kanye nokumelana nezinga lokushisa eliphezulu, ukumelana nokugqoka, nokuzinza kwamakhemikhali e-graphite powder. Ngakho-ke, ububanzi besicelo se-nanometer graphite powder bubanzi kakhulu embonini.

Ukusetshenziswa kwe-nano-graphite powder ekulungiseni amabhethri okugcina nakho kubanzi kakhulu. Ukwengeza i-nano-graphite kumabhethri asetshenzisiwe kungakhuphula umthamo wawo wokulondoloza ube ngaphezu kuka-90% wokwangempela futhi kunwebe impilo yawo yesevisi okungenani ngonyaka owodwa. Lokhu kusindisa kakhulu izindleko zokusebenzisa amabhethri okugcina futhi kudlala indima ebalulekile ekulawuleni ukungcoliswa kwebhethri nokuvikelwa kwemvelo.

I-graphite powder inezinhlobonhlobo zezicelo embonini. Ingasetshenziswa emikhakheni ehlukahlukene yokukhiqiza yezimboni. Ukusetshenziswa okuhlukile kwe-graphite powder kubangela amanani ahlukene. I-graphite powder inemiphumela emihle yokusetshenziswa emikhakheni efana nokugcotshwa kwezimboni, i-metallurgy, conductivity, nezinto eziphikisayo. Izinto ezifana nokusetshenziswa, usayizi wezinhlayiyana, kanye nohlobo lwe-graphite powder konke kungathinta intengo yayo.

Ukusetshenziswa kwe-graphite powder kuhlukene, ngakho-ke kunezinhlobo eziningi ze-graphite powder. Izinhlobo ezahlukene ze-graphite powder zinamanani ahlukene. I-Flake graphite ingacutshungulwa ibe yimpuphu ye-graphite yokucaciswa okuhlukahlukene nobukhulu bezinhlayiyana ngokusebenzisa imishini ehlukene yokuchoboza nezindlela zokukhiqiza. Njengomkhiqizi we-graphite powder, imininingwane yempushana ekhiqiziwe ye-graphite isukela ku-80 mesh kuya ku-15000 mesh. I-graphite powder inokucaciswa okuhlukile nobukhulu bezinhlayiyana, kanjalo nentengo yayo. Ngemva kokucutshungulwa ngamasu okukhiqiza, i-graphite powder ine-lubricity enhle kakhulu, ukumelana nokushisa okuphezulu, ukuqhutshwa kukagesi, ukumelana nokugqwala, njll. I-graphite powder nayo ingadlala indima ehambisanayo emikhakheni ehlukene yokukhiqiza yemboni.

Izinhlobo ze-graphite powder zifaka: I-Flake graphite powder, i-ultrafine graphite powder, i-nano graphite powder, i-colloidal graphite, i-graphite eyandisiwe, i-graphite enwebekayo, i-micro-powder graphite, njll., zonke lezi zimpushana ze-graphite zicutshungulwa ngamasu ahlukene okukhiqiza, futhi ukusetshenziswa kwawo kuhlukene. Impushana yegraphite isetshenziswa emikhakheni yokukhiqiza kawoyela wokugcoba, okokugcoba okuqinile, izinsimbi zegraphite, izitini eziphikisayo, ama-electrode egraphite, amabhulashi, ama-electrode angenayo ibhethri, njll. Zonke zinezinhlelo zokusebenza ezinhle kakhulu.

Isikhathi sokuthumela: May-15-2025