Ama-electrode e-graphite anamandla aphezulu kakhulu, ngokufaka ama-electrode ethusi esikhundleni sokwenza isikhunta, afinyeze kakhulu umjikelezo wokukhiqiza isikhunta, athuthukise ukukhiqiza kwezabasebenzi, futhi anciphise izindleko zokukhiqiza isikhunta. Eminyakeni yamuva nje, ngokwethulwa kokubumba okunembayo kanye nezibunzi ezisebenza kahle kakhulu (ngemijikelezo yesikhunta eya ngokuya ibe mifushane), izidingo zabantu zokukhiqiza isikhunta bezilokhu zikhuphuka ziya phezulu. Ngenxa yemikhawulo ehlukahlukene yama-electrode ethusi ngokwawo, iye yahluleka ngokuqhubekayo ukuhlangabezana nezidingo zokuthuthukiswa kwemboni yesikhunta. I-graphite, njengempahla ye-electrode ye-EDM, isetshenziswe kabanzi embonini yesikhunta ngenxa yezinzuzo zayo ezifana nokusebenza okuphezulu, isisindo esincane, ukubunjwa okusheshayo, izinga lokunweba eliphansi kakhulu, ukulahlekelwa okuphansi nokugqoka kalula. Kuyinto engenakugwemeka ukuthi izothatha indawo yama-electrode ethusi.

1. Izici Zezinto Ze-Graphite Electrode

Imishini ye-CNC ifaka isivinini sokucubungula ngokushesha, ukusebenza kahle okuphezulu nokugqoka okulula. Ijubane lokucubungula lemishini ye-graphite liphindwe izikhathi ezi-3 kuya kwezi-5 kune-electrode yethusi, futhi isivinini sokucubungula ukunemba sivelele ngokukhethekile. Ngaphezu kwalokho, amandla ayo aphezulu kakhulu. Kuma-electrode aphezulu kakhulu (ama-50 kuye kwangama-90) kanye nama-electrode ama-ultra-thin (0.2 kuya ku-0.5mm), awajwayele ukuwohloka ngesikhathi sokucubungula. Ngaphezu kwalokho, ezimweni eziningi, imikhiqizo idinga ukuba nomphumela omuhle kakhulu wokuthungwa. Lokhu kudinga ukuthi lapho kwenziwa ama-electrode, kufanele enziwe njengama-electrode abesilisa abalulekile ngangokunokwenzeka. Kodwa-ke, kukhona ukucaciswa kwamakhona okufihliwe okuhlukahlukene ngesikhathi sokukhiqizwa kwama-electrode abesilisa abalulekile. Ngenxa yempahla yokunquma kalula ye-graphite, le nkinga ingaxazululwa kalula futhi inani lama-electrode lingancishiswa kakhulu, okuyinto ama-electrode ethusi angakwazi ukuyifinyelela.

2. Ukwakhiwa kwe-EDM esheshayo, ukunwetshwa okuncane kokushisa nokulahlekelwa okuphansi: Ngenxa ye-conductivity kagesi engcono ye-graphite kuneyethusi, izinga lokukhishwa kwalo lishesha kunelethusi, libe yi-3 kuya ku-5 izikhathi zethusi. Ngaphezu kwalokho, ingakwazi ukumelana nomthamo omkhulu wamanje ngesikhathi sokuphuma, okuzuzisa kakhulu umshini wokukhipha ugesi omangelengele. Phakathi naleso sikhathi, ngaphansi kwevolumu efanayo, isisindo se-graphite siphindwe izikhathi ezingu-1/5 zethusi, okunciphisa kakhulu umthwalo we-EDM. Inezinzuzo ezinhle ekukhiqizeni ama-electrode amakhulu kanye nama-electrode abesilisa abalulekile. Izinga lokushisa le-sublimation le-graphite liyi-4200 ℃, okuyi-3 kuya kwezi-4 izikhathi zethusi (izinga lokushisa le-sublimation lethusi liyi-1100 ℃). Emazingeni okushisa aphezulu, shintsha

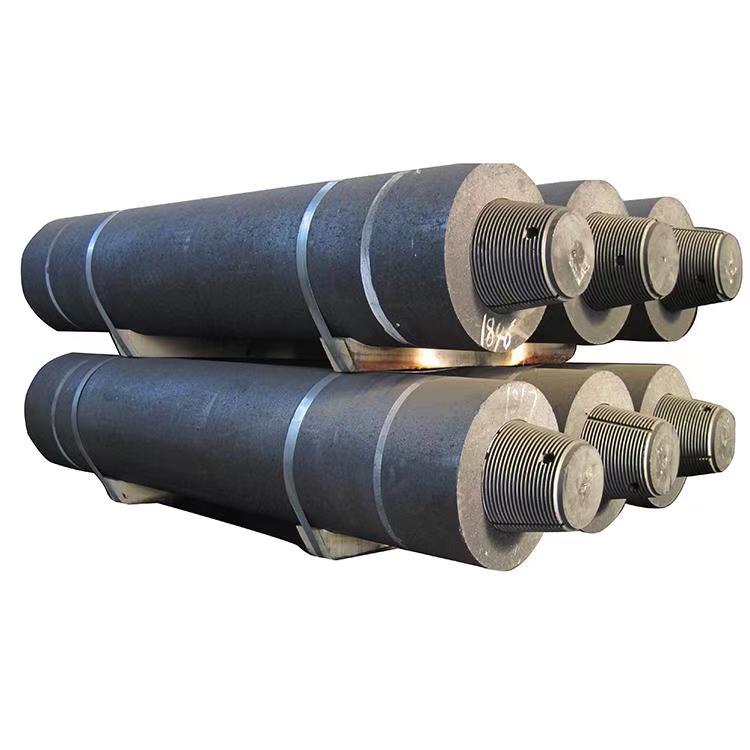

I-electrode ye-graphite yamandla aphezulu kakhulu

Incane kakhulu ngokuma (1/3 kuya ku-1/5 yethusi ngaphansi kwezimo ezifanayo zikagesi) futhi ayithambi. Amandla okukhipha angadluliselwa ku-workpiece ngokuphumelelayo nangokusetshenziswa okuphansi. Ngenxa yokuthi amandla e-graphite empeleni akhuphuka emazingeni okushisa aphezulu, anganciphisa ngokuphumelelayo ukulahlekelwa kokukhipha (ukulahlekelwa kwegraphite kungu-1/4 wethusi), ukuqinisekisa ikhwalithi yokucubungula.

3. Isisindo esilula kanye nezindleko eziphansi: Ezindlekweni zokukhiqiza zeqoqo lesikhunta, isikhathi somshini we-CNC, isikhathi se-EDM, nokugqoka kwe-electrode ye-akhawunti ye-electrode ngobuningi bezindleko eziphelele, futhi konke lokhu kunqunywa impahla ye-electrode ngokwayo. Uma kuqhathaniswa nethusi, isivinini somshini kanye nesivinini se-EDM se-graphite kokubili izikhathi ezingu-3 kuya kwezingu-5 kunezethusi. Phakathi naleso sikhathi, isici sokuguga okuncane kanye nokukhiqizwa kwe-electrode ebalulekile yegraphite kunganciphisa inani lama-electrode, ngaleyo ndlela kunciphise ukusetshenziswa kwezinto ezibonakalayo kanye nesikhathi somshini wama-electrode. Konke lokhu kunganciphisa kakhulu izindleko zokukhiqiza isikhunta

2. Izidingo kanye Nezimpawu Zokucutshungulwa Kwemishini Nogesi Kwe-Graphite Electrodes

1. Ukukhiqizwa kwama-electrode: Ukukhiqizwa kobuchwepheshe be-graphite electrode ikakhulukazi kusebenzisa amathuluzi omshini wesivinini esikhulu ukuze kucutshungulwe. Amathuluzi omshini kufanele abe nokuzinza okuhle, ngokunyakaza okufanayo nokuzinzile kwe-axis emithathu ngaphandle kokudlidliza. Ngaphezu kwalokho, ukunemba kokujikeleza kwezingxenye ezifana ne-shaft eyinhloko kufanele futhi kube kuhle ngangokunokwenzeka. I-electrode ingaphinda icutshungulwe kumathuluzi omshini ojwayelekile, kodwa inqubo yokubhala indlela yamathuluzi ihlukile kuleyo yama-electrode ethusi.

I-2.EDM yokukhipha ugesi kagesi machining graphite electrode kukhona carbon electrode. Ngenxa yokuthi i-graphite ine-conductivity kagesi enhle, ingasindisa isikhathi esiningi ekusetshenzisweni kokukhishwa kukagesi, okungenye yezizathu zokuthi kungani i-graphite isetshenziswa njenge-electrode.

3. Izici Zokucubungula Ze-Graphite Electrodes: I-graphite yemboni iqinile futhi i-brittle, ibangela ukuguga okubucayi kumathuluzi ngesikhathi somshini we-CNC. Ngokuvamile, kunconywa ukusebenzisa amathuluzi ahlanganiswe ne-alloy eqinile noma idayimane. Lapho rough machining graphite, ithuluzi kungenziwa ngqo ibekwe futhi off workpiece. Kodwa-ke, ngesikhathi sokuqeda imishini, ukuvimbela ukuqhekeka nokuqhekeka, ithuluzi elilula kanye nendlela yokunqamula ngokushesha kuvame ukwamukelwa.

Ngokuvamile, i-graphite ayivamile ukuphuka lapho ukujula kokusika kungaphansi kuka-0.2mm, futhi ikhwalithi engcono yodonga oluseceleni ingatholakala. Uthuli olukhiqizwe ngesikhathi se-CNC machining yama-electrode e-graphite lukhulu ngokuqhathaniswa futhi lungase luhlasele ama-rails omhlahlandlela, izikulufu zokuhola nama-spindle ethuluzi lomshini, njll. Lokhu kudinga ukuthi ithuluzi lomshini wokucubungula i-graphite libe namadivayisi ahambisanayo okubhekana nothuli lwe-graphite, nokusebenza kokuvala kwethuluzi lomshini kufanele futhi kube kuhle ngoba i-graphite inobuthi. I-graphite powder yinto ezwela kakhulu ekuphenduleni kwamakhemikhali. I-resistivity yayo iyashintsha ezindaweni ezahlukene, okusho ukuthi inani layo lokumelana liyahlukahluka. Kodwa-ke, kunento eyodwa ehlala ingashintshi: i-graphite powder ingenye yezinto ezinhle kakhulu ezingezona ezensimbi. Uma nje i-graphite powder igcinwe entweni evikelayo ngaphandle kokuphazamiseka, njengentambo encane, isazofakwa ugesi. Kodwa liyini inani lokumelana? Asikho isibalo esiqondile saleli xabiso noma, ngoba ubuhle be-graphite powder buyahlukahluka, futhi inani lokumelana ne-graphite powder elisetshenziswe ezintweni ezihlukahlukene nasezindaweni ezizungezile lizophinde lihluke.

Ungase ungazi ukuthi i-high-purity graphite powder nayo inokusetshenziswa okusebenzayo:

Ngokuvamile, i-rubber i-insulating. Uma i-conductivity kagesi iyadingeka, izinto eziqhutshwayo zidinga ukungezwa. I-graphite powder ine-conductivity kagesi enhle kakhulu kanye nezakhiwo zokudiliza zokugcoba. I-graphite icutshungulwa ibe yimpuphu ye-graphite, enezinto ezinhle kakhulu zokugcoba kanye ne-conductive. Ukuphakama kokuhlanzeka kwe-graphite powder, kungcono ukusebenza kwayo kwe-conductive. Izimboni eziningi zemikhiqizo yenjoloba ekhethekile zidinga i-rubber conductive. Khona-ke, ingabe i-graphite powder ingafakwa enjolweni ukuze kuqhutshwe ugesi? Impendulo inguyebo, kodwa kukhona nombuzo: Iyini ingxenye ye-graphite powder enjoloba? Amanye amabhizinisi asebenzisa ingxenye engeqile ku-30%, esetshenziswa emikhiqizweni yenjoloba engagugi njengamasondo ezimoto, njll. Kukhona nezimboni zenjoloba ezikhethekile ezisebenzisa ingxenye engu-100%. Imikhiqizo enjalo kuphela engahambisa ugesi. Isimiso esiyisisekelo se-conductivity ukuthi umqhubi akakwazi ukuphazanyiswa, njengocingo. Uma iphazamiseka phakathi ngeke ifakwe ugesi. I-graphite powder conductive ku-rubber conductive yi-conductor Uma i-graphite powder ivinjiwe i-rubber ye-insulating, ngeke isaqhuba ugesi. Ngakho-ke, uma ingxenye ye-graphite powder iphansi kakhulu, umphumela we-conductive ungase ube mpofu.

I-graphite powder yinto ezwela kakhulu ekuphenduleni kwamakhemikhali. I-resistivity yayo iyashintsha ezindaweni ezahlukene, okusho ukuthi inani layo lokumelana liyahlukahluka. Kodwa-ke, kunento eyodwa ehlala ingashintshi: i-high-purity graphite powder ingenye yezinto ezinhle kakhulu ezingezona ezensimbi. Uma nje i-graphite powder igcinwe entweni evikelayo ngaphandle kokuphazamiseka, njengentambo encane, isazofakwa ugesi. Kodwa liyini inani lokumelana? Asikho isibalo esiqondile saleli xabiso noma, ngoba ubuhle be-graphite powder buyahlukahluka, futhi inani lokumelana ne-graphite powder elisetshenziswe ezintweni ezihlukahlukene nasezindaweni ezizungezile lizophinde lihluke.

Isikhathi sokuthumela: May-09-2025