Izici ze-1.EDM zezinto ze-graphite.

1.1.Khipha isivinini somshini.

I-graphite iyinto engeyona eyensimbi enephuzu lokuncibilika eliphezulu kakhulu elingu-3, 650 ° C, kuyilapho ithusi linendawo yokuncibilika engu-1, 083 ° C, ngakho i-electrode yegraphite ingakwazi ukumelana nezimo ezinkulu zokumisa zamanje.

Lapho indawo yokukhipha kanye nesilinganiso sosayizi we-electrode kukhudlwana, izinzuzo zokusebenza kahle kakhulu komshini we-graphite zibonakala ngokucacile.

I-conductivity eshisayo ye-graphite yi-1/3 yethusi, futhi ukushisa okukhiqizwa phakathi nenqubo yokukhipha kungasetshenziswa ukususa izinto zensimbi ngokuphumelelayo.Ngakho-ke, ukusebenza kahle kokucubungula kwe-graphite kuphakeme kune-electrode yethusi ekucubunguleni okuphakathi nokuhle.

Ngokuvumelana nesipiliyoni sokucubungula, isivinini sokucutshungulwa kokukhishwa kwe-graphite electrode sishesha izikhathi ezingu-1.5~2 kuneso le-electrode yethusi ngaphansi kwezimo ezifanele zokusetshenziswa.

1.2.Ukusetshenziswa kwe-electrode.

I-electrode ye-graphite inohlamvu olukwazi ukumelana nezimo eziphakeme zamanje, ngaphezu kwalokho, ngaphansi kwesimo sokuhlelwa okufanele, okuhlanganisa izinto zokusebenza ze-carbon steel ezikhiqizwa ngesikhathi sokususwa komshini kokuqukethwe noketshezi olusebenzayo ekubolekeni kwezinga lokushisa eliphezulu kwezinhlayiya ze-carbon, umphumela we-polarity, ngaphansi isenzo sokususwa kwengxenye kokuqukethwe, izinhlayiya zekhabhoni zizonamathela endaweni ye-electrode ukuze zenze isendlalelo esivikelayo, ziqinisekise i-electrode yegraphite ekulahlekelweni okuncane ekusetshenzisweni okuqinile, noma ngisho "ne-zero waste".

Ukulahleka kwe-electrode okuyinhloko ku-EDM kuvela emishinini enzima.Nakuba izinga lokulahlekelwa liphezulu ezimeni zokusethwa kokuqeda, ukulahlekelwa kukonke nakho kuphansi ngenxa yesabelo somshini esincane ebekelwe izingxenye.

Ngokuvamile, ukulahlekelwa kwe-electrode ye-graphite kungaphansi kwaleyo ye-electrode yethusi emshinini onzima wamanje omkhulu futhi kancane ngaphezu kwalokho kwe-electrode yethusi ekuqedeni imishini.Ukulahlekelwa kwe-electrode ye-graphite electrode kuyafana.

1.3.Izinga eliphezulu.

Ububanzi bezinhlayiyana ze-graphite material buthinta ngokuqondile ukuhwaqeka kwendawo ye-EDM.Ubukhulu be-diameter buncane, i-surface roughness ephansi ingatholakala.

Eminyakeni embalwa edlule kusetshenziswa izinhlayiyana ze-phi 5 microns ku-diameter graphite material, indawo engcono kakhulu ingafinyelela kuphela i-VDI18 edm (Ra0.8 microns), kulezi zinsuku ububanzi obusanhlamvu bezinto ze-graphite bukwazile ukuzuza ngaphakathi kwama-microns angu-3 we-phi, indawo engcono kakhulu. ingafinyelela izinga elizinzile le-VDI12 edm (Ra0.4 mu m) noma izinga eliyinkimbinkimbi, kodwa i-electrode yegraphite ukuze isibuko se-edm.

Izinto zethusi zine-resistivity ephansi kanye nesakhiwo esihlangene, futhi singacutshungulwa ngokuzinzile ngaphansi kwezimo ezinzima.Ubukhulu obungaphezulu bungaba ngaphansi kuka-Ra0.1 m, futhi bungacutshungulwa ngesibuko.

Ngakho-ke, uma imishini yokukhipha iphishekela indawo enhle kakhulu, kufaneleka kakhulu ukusebenzisa izinto zethusi njenge-electrode, okuyinzuzo enkulu ye-electrode yethusi ngaphezu kwe-graphite electrode.

Kodwa i-electrode yethusi ngaphansi kwesimo sokusetha okukhulu kwamanje, indawo ye-electrode kulula ukuba ibe lukhuni, ibonakale ngisho nokuqhekeka, futhi izinto ze-graphite bezingeke zibe nale nkinga, imfuneko yobunzima obuphezulu be-VDI26 (Ra2.0 microns) mayelana nokucubungula isikhunta, usebenzisa i-electrode ye-graphite ingenziwa kusukela ekuqhumeni kuya ekucutshungulweni okuhle, ibona umphumela we-uniform surface, amaphutha angaphezulu.

Ukwengeza, ngenxa yesakhiwo esihlukile se-graphite nethusi, indawo yokugqwala yokukhishwa kwendawo ye-graphite electrode ivame kakhulu kune-electrode yethusi.Ngakho-ke, lapho ubulukhuni obufanayo obuphezulu be-VDI20 noma ngaphezulu bucutshungulwa, ubumbudumbudu obungaphezulu bomsebenzi ocutshungulwa yi-graphite electrode buhluke kakhulu, futhi lo mphumela wendawo yokusanhlamvu ungcono kunomphumela ophumayo ongaphezulu we-electrode yethusi.

1.4.Ukunemba komshini.

I-coefficient yokwanda okushisayo kwe-graphite material incane, i-coefficient yokwandiswa okushisayo kwezinto zethusi izikhathi ezingu-4 ze-graphite material, ngakho-ke ekucubungulweni kokukhishwa, i-graphite electrode ayinakwenzeka ukuguquguquka kune-electrode yethusi, engathola ukuzinza futhi ukunemba kokucubungula okuthembekile.

Ikakhulukazi lapho kucutshungulwa ubambo olujulile noluncane, izinga lokushisa eliphezulu lasendaweni lenza i-electrode yethusi igobe kalula, kodwa i-graphite electrode ayigobi.

Ku-electrode yethusi enesilinganiso esikhulu sobubanzi bobubanzi, inani elithile lokunweba okushisayo kufanele linxeshezelwe ukuze kulungiswe usayizi phakathi nokulungiselelwa komshini, kuyilapho i-electrode yegraphite ingadingeki.

1.5.Isisindo se-Electrode.

I-graphite impahla iminyene kancane kunethusi, futhi isisindo se-graphite electrode yevolumu efanayo yi-1/5 kuphela yaleso se-electrode yethusi.

Kungabonakala ukuthi ukusetshenziswa kwe-graphite kulungele kakhulu i-electrode enomthamo omkhulu, okunciphisa kakhulu umthwalo we-spindle yethuluzi lomshini we-EDM.I-electrode ngeke ibangele ukuphazamiseka ekubambeni ngenxa yesisindo sayo esikhulu, futhi izokhiqiza ukugudluka kokuphambuka ekucubunguleni, njll. Kungabonakala ukuthi kubaluleke kakhulu ukusebenzisa i-graphite electrode ekucubunguleni isikhunta esikhulu.

1.6.Ubunzima bokukhiqiza i-Electrode.

Ukusebenza kwemishini yezinto ze-graphite kuhle.Ukumelana nokusika kungu-1/4 kuphela wethusi.Ngaphansi kwezimo ezilungile zokucubungula, ukusebenza kahle kwe-electrode yokugaya i-graphite izikhathi ezi-2 ~ 3 kune-electrode yethusi.

I-electrode yegraphite kulula ukuyisula i-Angle, futhi ingasetshenziswa ukucubungula ucezu lokusebenza okufanele luqedwe ngama-electrode amaningi lube yi-electrode eyodwa.

Isakhiwo sezinhlayiya esiyingqayizivele se-graphite material sivimbela ama-burrs ukuthi angenzeki ngemva kokugaya nokwakheka kwe-electrode, engahlangabezana ngokuqondile nezidingo zokusetshenziswa lapho ama-burrs engasuswa kalula ekumodeleni okuyinkimbinkimbi, ngaleyo ndlela aqede inqubo yokupholisha ngesandla kwe-electrode futhi agweme ukuma. iphutha lokushintsha nosayizi elibangelwa ukupholisha.

Kumele kuqashelwe ukuthi, ngenxa yokuthi i-graphite iwukuqoqwa kothuli, i-graphite yokugaya izokhiqiza uthuli oluningi, ngakho umshini wokugaya kufanele ube nedivayisi yokuqoqa uphawu nothuli.

Uma kudingekile ukusebenzisa i-edM ukucubungula i-electrode ye-graphite, ukusebenza kwayo kokucubungula akufani nempahla yethusi, ijubane lokusika lihamba kancane ngo-40% kunethusi.

1.7.Ukufakwa nokusebenzisa i-Electrode.

Izinto ze-graphite zinempahla enhle yokubopha.Ingasetshenziselwa ukuhlanganisa i-graphite ne-fixture ngokugaya i-electrode kanye nokukhipha, okungahle konga inqubo yokufaka imbobo yesikulufu kumshini we-electrode futhi yonge isikhathi sokusebenza.

I-graphite material i-brittle kuqhathaniswa, ikakhulukazi i-electrode encane, emincane futhi ende, okulula ukuphuka lapho ingaphansi kwamandla angaphandle ngesikhathi sokusetshenziswa, kodwa ingakwazi ngokushesha ukuthi i-electrode yonakalisiwe.

Uma i-electrode yethusi, izogoba kuphela futhi ingaphuli, okuyingozi kakhulu futhi okunzima ukuyithola ngesikhathi sokusebenzisa, futhi izoholela kalula ku-scrap of workpiece.

1.8.Intengo.

Impahla yethusi iyinsiza engavuseleleki, inkambiso yentengo izobiza kakhulu, kuyilapho intengo yezinto ze-graphite ijwayele ukuzinza.

Intengo yezinto zethusi ezikhuphuka eminyakeni yamuva, abakhiqizi abakhulu be-graphite abathuthukisa inqubo ekukhiqizeni i-graphite benza inzuzo yayo yokuncintisana, manje, ngaphansi kwevolumu efanayo, ukujwayelekile kwentengo yezinto ezibonakalayo ze-graphite electrode kanye nentengo yezinto zokwakha ze-electrode zethusi impela, kodwa i-graphite ingakwazi ukufeza ukucubungula okusebenzayo, kunokusetshenziswa kwe-electrode yethusi ukuze kugcinwe inani elikhulu lamahora okusebenza, okulingana nokunciphisa izindleko zokukhiqiza ngokuqondile.

Ukufingqa, phakathi kwezici ezingu-8 ze-edM ze-graphite electrode, izinzuzo zayo zisobala: ukusebenza kahle kwe-electrode yokugaya kanye nokucubungula ukukhishwa kungcono kakhulu kune-electrode yethusi;I-electrode enkulu inesisindo esincane, ukuzinza okuhle kwe-dimensional, i-electrode encane akulula ukuyishintsha, futhi ukuthungwa kwendawo kungcono kune-electrode yethusi.

Ukungalungi kwezinto ze-graphite ukuthi akufanelekile ukucutshungulwa kokukhipha okuphezulu ngaphansi kwe-VDI12 (Ra0.4 m), futhi ukusebenza kahle kokusebenzisa i-edM ukwenza i-electrode iphansi.

Kodwa-ke, ngokombono ongokoqobo, esinye sezizathu ezibalulekile ezithinta ukukhuthazwa ngempumelelo kwezinto ze-graphite e-China ukuthi umshini okhethekile wokucubungula i-graphite uyadingeka kuma-electrode okugaya, okubeka phambili izidingo ezintsha zokucubungula imishini yamabhizinisi esikhunta, amanye amabhizinisi amancane. angase angabi naso lesi simo.

Ngokuvamile, izinzuzo zama-electrode e-graphite zihlanganisa izikhathi eziningi zokucubungula i-edM, futhi zifanele ukuduma nokusetshenziswa, ngezinzuzo ezinkulu zesikhathi eside.Ukuntuleka kokucubungula okuphezulu kwendawo kungenziwa ngokusetshenziswa kwama-electrode ethusi.

2.Ukukhethwa kwezinto ze-graphite electrode ze-EDM

Ngezinto ze-graphite, ikakhulukazi izinkomba ezine ezilandelayo ezinquma ngokuqondile ukusebenza kwezinto:

1) I-avareji yezinhlayiyana zobubanzi bento

Ububanzi bezinhlayiya ezimaphakathi zezinto ezibonakalayo buthinta ngokuqondile isimo sokuphuma kwezinto.

Incane inhlayiya evamile ye-graphite material, lapho ukukhishwa kufana kakhulu, isimo sokukhishwa sizinzile, ikhwalithi ephezulu ingcono, futhi ukulahlekelwa kuncane.

Uma kukhulu usayizi wezinhlayiyana ezimaphakathi, izinga elingcono lokususa lingatholwa ngomshini onzima, kodwa umphumela ongaphezulu wokuqeda awulungile futhi ukulahleka kwe-electrode kukhulu.

2) Amandla okugoba wento

Amandla aguquguqukayo wento esetshenziswayo kuwukubonakaliswa okuqondile kwamandla ayo, okubonisa ukucinana kwesakhiwo sayo sangaphakathi.

Izinto ezinamandla aphezulu zinokusebenza okuhle kokumelana nokukhipha.Ukuze uthole i-electrode ngokunemba okuphezulu, impahla enamandla amahle kufanele ikhethwe ngangokunokwenzeka.

3) Ukuqina kosebe lwento

I-graphite inzima kunezinto zensimbi, futhi ukulahlekelwa kwethuluzi lokusika kukhulu kunokwensimbi yokusika.

Ngesikhathi esifanayo, ubulukhuni obukhulu bezinto ze-graphite ekulawuleni ukulahlekelwa kokukhishwa kungcono.

4) Ukuphikiswa okungokwemvelo kwento

Izinga lokukhishwa kwezinto ze-graphite ezinokumelana okuphezulu kwemvelo lizohamba kancane kunalelo elinokumelana okuphansi.

Ukuphakama kwe-resistivity yemvelo, kuncane ukulahlekelwa kwe-electrode, kodwa ukuphakama kwe-resistivity yemvelo, ukuzinza kokukhishwa kuzothinteka.

Njengamanje, kunamabanga amaningi ahlukene e-graphite atholakala kubahlinzeki be-graphite abahamba phambili emhlabeni.

Ngokuvamile ngokwesilinganiso sezinhlayiyana ububanzi bezinto ze-graphite okufanele zihlukaniswe, ububanzi bezinhlayiya ≤ 4 m buchazwa njenge-graphite enhle, izinhlayiya ku-5 ~ 10 m zichazwa njenge-graphite ephakathi, izinhlayiya eziku-10 m ngaphezulu zichazwa njenge-graphite eqinile.

Ubukhulu bezinhlayiyana buncane, uma impahla ibiza kakhulu, impahla ye-graphite efanelekile ingakhethwa ngokuvumelana nezidingo kanye nezindleko ze-EDM.

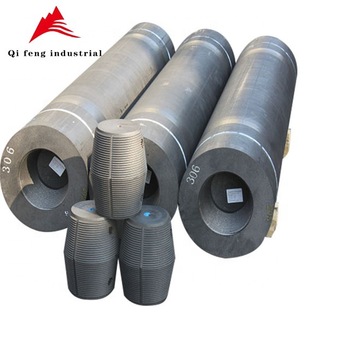

3.Ukwenziwa kwe-graphite electrode

I-electrode ye-graphite yenziwa ngokuyinhloko ngokugaya.

Ngokombono wokucubungula ubuchwepheshe, i-graphite nethusi yizinto ezimbili ezihlukene, futhi izici zabo zokusika ezihlukene kufanele zenziwe kahle.

Uma i-electrode ye-graphite icutshungulwa yinqubo ye-electrode yethusi, izinkinga zizokwenzeka nakanjani, njengokuphuka njalo kweshidi, okudinga ukusetshenziswa kwamathuluzi afanele okusika kanye nemingcele yokusika.

Ukwenza i-electrode ye-graphite kunokugqoka kwethuluzi le-electrode yethusi, uma kucatshangelwa umnotho, ukukhetha ithuluzi le-carbide kunomnotho kakhulu, khetha ithuluzi ledayimane lokunamathela (elibizwa ngokuthi ummese we-graphite) intengo ibiza kakhulu, kodwa ithuluzi lokumboza idayimane impilo ende yenkonzo, ukunemba okuphezulu kokucubungula, inzuzo yezomnotho iyonke yinhle.

Usayizi we-Engeli yangaphambili yethuluzi nayo ithinta impilo yayo yesevisi, i-Angle engu-0° yangaphambili yethuluzi izoba phezulu ngo-50% kune-Angle yangaphambili engu-15° yokuphila kwesevisi yethuluzi, ukuzinza kokusika nakho kungcono, kodwa i-Angle enkulu, i-machining surface engcono kakhulu, ukusetshenziswa kwe-15 ° Angle yethuluzi kungafinyelela indawo engcono kakhulu yomshini.

Ijubane lokusika emishinini lingashintshwa ngokuya ngokuma kwe-electrode, imvamisa i-10m/min, efana nomshini we-aluminium noma wepulasitiki, ithuluzi lokusika lingaba ngqo futhi livale ucezu lokusebenzela emashini amabi, kanye nesimo se-Angle. ukuwohloka nokuhlukaniswa kulula ukwenzeka ekuqedeni imishini, futhi indlela yommese okhanyayo ukuhamba ngokushesha ivame ukwamukelwa.

I-electrode ye-graphite enqubweni yokusika izokhiqiza uthuli oluningi, ukuze ugweme izinhlayiya ze-graphite eziphefumulelwe umshini wokuphotha kanye nesikulufa, kunezixazululo ezimbili eziyinhloko okwamanje, enye iwukusebenzisa umshini okhethekile wokucubungula i-graphite, enye isikhungo esivamile sokucubungula. refit, ifakwe idivayisi ekhethekile yokuqoqa uthuli.

Umshini wokugaya okhethekile we-graphite high speed emakethe unokusebenza okuphezulu kokugaya futhi ungaqedela kalula ukukhiqizwa kwama-electrode ayinkimbinkimbi ngokunemba okuphezulu kanye nekhwalithi enhle yendawo.

Uma i-EDM idingeka ukwenza i-electrode ye-graphite, kunconywa ukusebenzisa into enhle ye-graphite enobubanzi bezinhlayiyana ezincane.

Ukusebenza komshini we-graphite kubi, i-diameter yezinhlayiyana incane, izinga eliphezulu lokusika lingatholakala, futhi izinkinga ezingavamile ezifana nokuphuka kwezintambo njalo kanye ne-surface fringe zingagwenywa.

Imingcele ye-4.EDM ye-graphite electrode

Ukukhethwa kwemingcele ye-EDM yegraphite nethusi kuhluke kakhulu.

Imingcele ye-EDM ikakhulukazi ihlanganisa okwamanje, ububanzi be-pulse, i-pulse gap kanye ne-polarity.

Okulandelayo kuchaza isisekelo sokusetshenziswa okuphusile kwale mingcele emikhulu.

Ukuminyana kwamanje kwe-electrode yegraphite ngokuvamile kungu-10~12 A/cm2, kukhulu kakhulu kunaleyo ye-electrode yethusi.Ngakho-ke, phakathi kobubanzi bamanje obuvunyelwe endaweni ehambisanayo, okukhudlwana okwamanje kukhethiwe, ngokushesha isivinini sokucubungula ukukhishwa kwe-graphite sizoba, ukulahlekelwa kwe-electrode kuyoba kuncane, kodwa ukuqina kwendawo kuyoba mkhulu.

Uma kukhulu ububanzi be-pulse, ukulahlekelwa kwe-electrode kuyoba okuphansi.

Kodwa-ke, ububanzi be-pulse obukhudlwana buzokwenza ukuzinza kokucubungula kube kubi kakhulu, futhi isivinini sokucubungula sihambe kancane kanye nendawo engaphezulu.

Ukuze kuqinisekiswe ukulahleka kwe-electrode ephansi ngesikhathi somshini onzima, ububanzi be-pulse obukhulu kakhulu ngokuvamile busetshenziswa, obungabona ngempumelelo ukulahlekelwa okuphansi komshini we-graphite electrode uma inani liphakathi kuka-100 no-300 wase-US.

Ukuze kutholwe umphumela omuhle wokukhipha kanye nezinzile, ububanzi be-pulse encane kufanele kukhethwe.

Ngokuvamile, ububanzi be-pulse ye-graphite electrode cishe bungaphansi kwama-40% kune-electrode yethusi.

Igebe le-pulse lithinta kakhulu isivinini somshini wokukhipha kanye nokuzinza komshini.Uma likhulu inani, kuzoba ngcono ukuzinza kwemishini, okuwusizo ekutholeni ukufana kwendawo engcono, kodwa isivinini somshini sizoncishiswa.

Ngaphansi kwesimo sokuqinisekisa ukuzinza kokucubungula, ukusebenza kahle okuphezulu kokucubungula kungatholakala ngokukhetha igebe elincane le-pulse, kodwa lapho isimo sokukhishwa singazinzile, ukusebenza kahle okuphezulu kokucubungula kungatholakala ngokukhetha igebe elikhulu le-pulse.

Kumashini wokukhipha ama-electrode e-graphite, igebe lokushaya kwenhliziyo nobubanzi be-pulse kuvame ukusetha ku-1:1, kuyilapho kumshini we-electrode yethusi, i-pulse gap nobubanzi be-pulse kuvame ukusetha ku-1:3.

Ngaphansi kokucutshungulwa kwe-graphite okuzinzile, isilinganiso esifanayo phakathi kwegebe lokushaya kwenhliziyo nobubanzi be-pulse singalungiswa sibe ngu-2:3.

Endabeni yokukhishwa kwe-pulse encane, kunenzuzo ukwenza isendlalelo sokumboza endaweni ye-electrode, esiza ukunciphisa ukulahlekelwa kwe-electrode.

Ukukhethwa kwe-polarity ye-graphite electrode ku-EDM ngokuyisisekelo kufana nalokho kwe-electrode yethusi.

Ngokomphumela we-polarity we-EDM, i-positive polarity machining ivame ukusetshenziswa lapho kulungiswa insimbi yokufa, okungukuthi, i-electrode ixhunywe esigxotsheni esihle sokunikezwa kwamandla, futhi ucezu lokusebenza luxhunywe esigxotsheni esibi sokunikezwa kwamandla.

Ngokusebenzisa ububanzi obukhulu bamanje kanye ne-pulse, ukukhetha umshini we-polarity omuhle kungafinyelela ukulahlekelwa kwe-electrode ephansi kakhulu.Uma i-polarity ingalungile, ukulahlekelwa kwe-electrode kuzoba kukhulu kakhulu.

Kuphela lapho ubuso budingeka ukuthi bucutshungulwe kahle ngaphansi kwe-VDI18 (Ra0.8 m) futhi ububanzi be-pulse buncane kakhulu, ukucubungula okungalungile kwe-polarity kusetshenziselwa ukuthola ikhwalithi engcono, kodwa ukulahlekelwa kwe-electrode kukhulu.

Manje amathuluzi omshini we-CNC edM afakwe amapharamitha womshini wokukhipha i-graphite.

Ukusetshenziswa kwamapharamitha kagesi kuhlakaniphile futhi kungenziwa ngokuzenzakalelayo ngohlelo lochwepheshe lwethuluzi lomshini.

Ngokuvamile, umshini ungamisa amapharamitha wokucubungula alungiselelwe ngokukhetha ipheya yezinto ezibonakalayo, uhlobo lohlelo lokusebenza, inani lokuma okungaphezulu kanye nokufaka indawo yokucubungula, ukujula kokucubungula, ukukala usayizi we-electrode, njll. Ngesikhathi sohlelo.

Isethelwe i-graphite electrode yomtapo wolwazi wethuluzi lomshini we-edm amapharamitha wokucubungula acebile, uhlobo lwezinto ezibonakalayo lungakhetha ku-graphite eqinile, i-graphite, i-graphite ihambisana nezinto ezihlukahlukene zezinto zokusebenza, ukuhlukanisa uhlobo lohlelo lokusebenza lwezinga elijwayelekile, i-groove ejulile, iphuzu elicijile, elikhulu. indawo, umgodi omkhulu, njengenhlawulo, futhi ihlinzeka ngokulahleka okuphansi, okujwayelekile, ukusebenza kahle okuphezulu nokunye okuningi kokucubungula ukukhetha okubalulekile.

5.Isiphetho

Izinto ezintsha ze-graphite electrode kufanelekile ukuthandwa ngamandla futhi izinzuzo zayo zizoqashelwa kancane kancane futhi zamukelwe imboni yasekhaya yokukhiqiza isikhunta.

Ukukhethwa okulungile kwezinto zokwenziwa kwe-graphite electrode kanye nokuthuthukiswa kwezixhumanisi zobuchwepheshe ezihlobene kuzoletha ukusebenza kahle okuphezulu, ikhwalithi ephezulu kanye nenzuzo yezindleko eziphansi emabhizinisini akhiqiza isikhunta.

Isikhathi sokuthumela: Dec-04-2020